The climate litigation case against Royal Dutch Shell was brought to court in December 2020 by Milieudefensie, and awaits a verdict by 26 May. Many wonder what concrete steps Shell will announce ahead of the shareholder meeting in March of this year to eventually achieve its self-defined target of reducing the carbon content of its energy products by 65% in 2050.

Shell’s decarbonization strategy could be built on three pillars, namely (1) scaling up renewable energy, (2) addressing intermittency from renewables by large-scale energy storage, and (3) developing carbon-free fuels, notably for the aviation sector.

- Scale up renewables

Rapidly expanding renewable capacity will be key to move the energy transition forward. To get an understanding of the scale required let’s consider how much oil and gas Shell produces annually. In its 2019 annual report Shell reports a production of 1.001 million barrels of oil equivalent, which presumably relates to oil and gas production combined. Since another source mentions a production 666 million barrels of crude oil, we will assume that natural gas production is 335 million boe.

How much final energy does this embody? Let’s consider crude oil first. A visual on the internet, based on Chevron data, presents the products one can make from a barrel of oil. Not all production from crude oil is for energy, and a substantial part is needed for the production of petrochemicals. Nevertheless, energy uses may be considered a key driver for the production of fossil fuels. Should the production of fossil energy be phased out, this will likely boost the price of fossil feedstocks for the (petro-)chemical industry. This will greatly support business cases for producing biobased, circular and/or other alternatives to fossil-based products.

Figure 1 What can you make from one barrel of US crude oil? Source: JWN Energy, based on Chevron data.

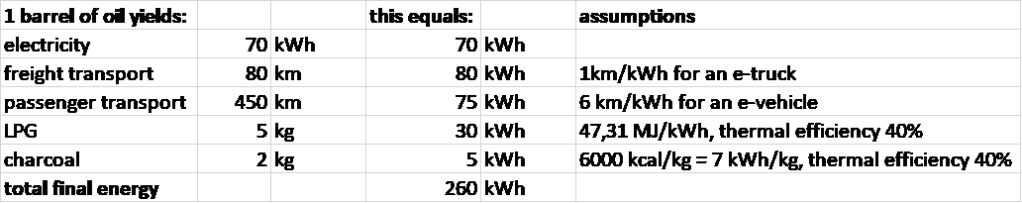

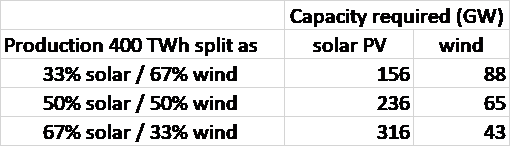

Energy uses derived from 1 barrel of crude oil add up to 260 kWh final energy (see Table 1). For the entire 2019 crude oil production this adds up to 173 TWh (Table 2). Combined with the final energy provided by natural gas this results in around 400 TWh of final energy of the oil and gas production combined. Table 3 shows how this amount may be provided by various combinations of wind and solar capacity. If a third is to be produced by solar PV and the remainder by on and offshore wind, Shell would need to work to install 156 GW solar PV and 88 GW wind capacity by 2050 – by and large 1,5 times the cumulative global capacity installed to date. Whilst this is a considerable effort it is certainly doable, considering vast cost reductions for renewable energy in the recent past and in years to come.

Table 1 Energy products resulting from a barrel of average US crude oil, rounded figures. Non-energy uses are excluded. Based on Chevron data presented by JWN Energy

Table 2 Shell production crude oil and natural gas incl. estimated final energy

Table 3 Renewable capacity required to produce 400 TWh of green electricity

Clearly, this will not be the end of it. Shell will also need to innovate and produce alternative fuels to serve energy needs that cannot be fulfilled by electricity. These include biofuels as well as fuels produced with power-to-liquid technology.

2. Address intermittency by large-scale energy storage

The intermittency of renewable energy sources may be addressed by improved interconnections, demand response management, and energy storage. Whilst transmission and DRM are typically dealt with by grid operators, Shell could become active in the arena of large scale energy storage. In fact, this could become the most profitable part of the energy transition, since energy storage facilities may deliver electricity when supply is scarce and prices are high.

In a fully renewable energy system the demand for storage is substantial. This overview article suggests that future electricity supply from storage facilities may be on the order of 1000 GWh in both the EU and the US, assuming systems with a balanced mix of PV and wind. Considering that the EU and US make up 10% of global populations, the global need for such backup supply could be estimated at least 10 TWh.

Part of this demand will be filled in by batteries, notably for residential and small to medium scale commercial applications. Batteries providing 100 kW power (with dimensions of a large fridge) are fully commercial, and the cost of batteries has come down rapidly. This cost reduction was driven mainly by the upscaling of electric vehicles causing the price of a lithium-ion battery pack to be decimated. Costs of utility-scale batteries are expected to come down by 21-67% by 2030.

Next to this, stationary fuel cells may play a role for backup at larger scales. Currently, the US and South Korea are leading this market, and last year, a 50 MW hydrogen power plant became operational in Seoul. Feeding stationary fuel cells with green hydrogen would imply that roughly 50% of primary energy is lost during electrolysis (assuming 80% efficiency) and in the fuel cell (efficiency up to 60%). As a result, 20 TWh would need to be produced from renewable sources. If this is done using solar panels in high irradiation areas this would require no more than 125 km2 of solar panels.

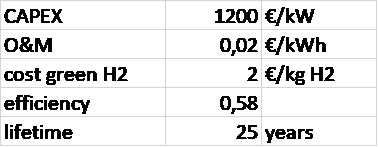

What would energy storage until 2030 cost? Targets for stationary fuel cells were laid down in the 2018 update of the Hydrogen Europe research program, referred to in this JRC report and summarized below. We assume that green hydrogen costs 2 €/kg and that the generated electricity is sold for 0,18 €/kWh. A 1 MW fuel cell that is used 10% of the time could then easily generate a positive cashflow of 15 k€/year. Energy storage in utility-scale batteries are likely attractive, as batteries lack the inefficiencies of a system based on subsequent electrolysis and fuel cell production.

Table 4 2030 targets for large scale stationary fuel cell. Source: JRC (2019)

3. Sustainable aviation fuels

A third pillar of the Shell net zero strategy will need to be sustainable fuels, notably for aviation.

The dominant approach for decarbonizing the aviation sector to date has been reforestation. In theory, stable forests could indeed absorb the CO2 emitted by the sector. In 2019, 1 billion litres of kerosene (similar to the number of kgs) were used every day. Assuming that the carbon content of kerosene is 85%, while it is 27% for CO2, this resulted in 1 Gt CO2 emissions for the whole year. To compensate this 20-200 billion mature trees would be required, assuming CO2 absorption rates between 5 and 50 kg CO2/yr, depending on species and conditions. Unfortunately, global forests are in decline. While the global forest area is around 4 billion ha today, the rate of deforestation was estimated at 10 million hectares per year between 2015 and 2020. At this rate, global forests will almost have halved by the end of next century. Massive reforestation is required to reverse this trend and increase the amount of carbon stored in woods. However, if such reforestation efforts are used to compensate for current CO2 emissions, no carbon will be sequestered in net terms.

Zero carbon fuels are key for a truly sustainable aviation sector. To develop and upscale such fuels Shell currently concentrates on biobased jet fuels, for which the company collaborates with SkyNRG. These fuels are currently produced from waste oils, which are in limited supply. Other feedstocks would need to be utilized, such as agricultural residues and municipal waste, but these are in high demand also for alternative uses in sustainable agriculture and in the energy sector. It is unrealistic, therefore, to assume that biobased aviation fuels can ever be made available at the large scale required. Next to this, their production requires large volumes of water and puts significant claims on land use, which negatively impacts the overall sustainability of biofuels (link).

An alternative is power-to-liquids (PtL) technology. PtL holds prospects of large scale application, and outperforms biobased fuel production in sustainability performance, notably with regards to water and landuse. PtL technology comprises various steps:

- The production of green hydrogen via electrolysis, using renewable electricity e.g. from solar PV at low latitudes, which is cheap. Also, the cost of electrolysis has been projected to fall 40% until 2030. Besides, high-temperature electrolysis (to be demonstrated at scale) would improve the efficiency (link).

- The sourcing of CO2, which for bulk production would need to be done by extraction from air. This is a critical step in the process, since the technology of direct air capture still hovers around TRL 6, meaning that the technology has been demonstrated but still needs prototyping. Today, 15 direct air capture facilities are in operation, capturing 9 kt CO2 every year, and a 1 MtCO2/yr capture plant is under development.

- Synthesis from hydrogen and CO2 into fuel. This can be done via synthesis and conversion of methanol, or via synthesis of hydrocarbons in the Fischer-Tropsch process. Both are applied commercially.

A complete Power-to-Liquids pathway has already been demonstrated, and by 2023 an industrial PtL plant producing 10 mln liters or renewable fuel annually will become operational. The main challenge for Power-to-Liquids technology today is the cost of production, arising from the cost of capital and current process inefficiencies. Costs will undoubtedly come down with further demonstration and upscaling of the technology. To advance PtL technology and bring down costs Shell should aim for demonstrations of the full PtL process to further system integration and improve efficiencies.

Good one

LikeLike